Shaft seals are an essential component in many industrial applications, including pumps, compressors, and turbines. They are designed to prevent the leakage of fluids or gases from the rotating shafts of these machines. In this article, we will explore what a shaft seal is, how it works, and the different types of shaft seals available.

What is a Shaft Seal?

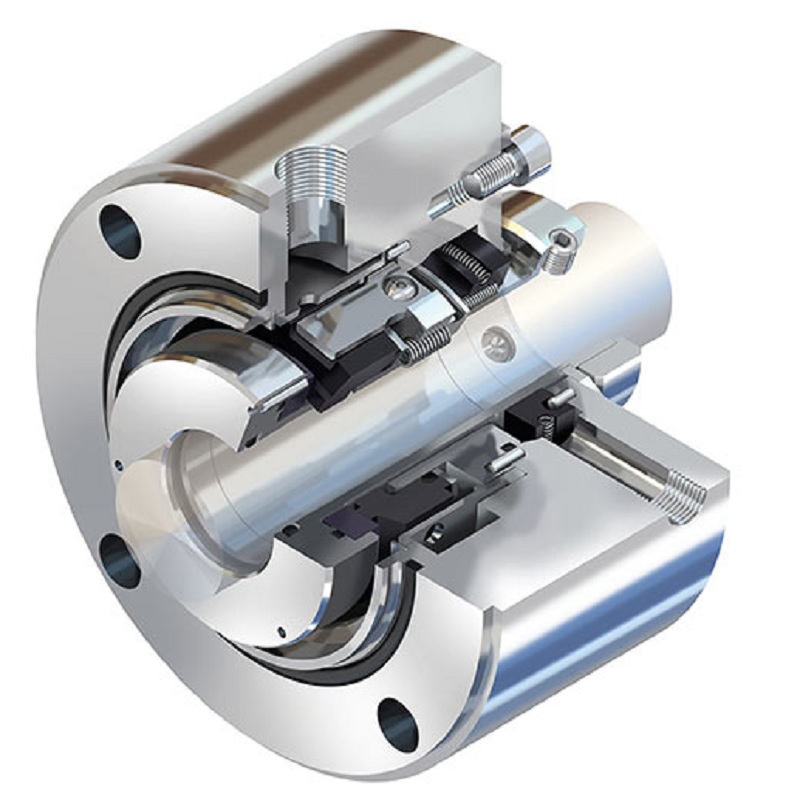

A shaft seal, also known as a radial shaft seal or lip seal, is a mechanical seal that is used to prevent the leakage of fluids or gases from the rotating shaft of a machine. It is typically made up of a flexible sealing lip that is in contact with the shaft and a stationary housing that holds the lip in place.

How Does a Shaft Seal Work?

Shaft seals work by creating a barrier between the rotating shaft and the stationary housing. The sealing lip is in contact with the shaft and rotates with it, creating a dynamic seal. The lip is designed to maintain contact with the shaft even as it moves up and down due to changes in temperature or pressure.

The stationary housing, also known as the seal case, holds the sealing lip in place and prevents it from moving too far away from the shaft. The housing is typically made of metal and is designed to withstand the pressure and temperature of the fluid or gas being sealed.

Types of Shaft Seals:

There are several types of shaft seals available, each with its own unique design and application. Some of the most common types include:

- Radial Lip Seal: This is the most common type of shaft seal and is used in a wide range of applications. It consists of a flexible sealing lip that is in contact with the shaft and a stationary housing that holds the lip in place.

- Mechanical Seal: This type of seal uses two flat surfaces that are pressed together to create a seal. It is typically used in high-pressure applications and is more expensive than a radial lip seal.

- Labyrinth Seal: This type of seal uses a series of grooves and ridges to create a barrier between the rotating shaft and the stationary housing. It is typically used in applications where there is a high risk of contamination.

Conclusion:

Shaft seals are an essential component in many industrial applications, and understanding how they work is crucial for ensuring the safe and efficient operation of machines. By choosing the right type of shaft seal for your application, you can prevent leaks and reduce downtime, ultimately saving time and money.